Last month’s newsletter discussed surface finish roughness. This month we are going to talk about title block tolerances and significant digits. This topic was suggested by Lou at Brookhaven National Labs. Thank you Lou!

Nearly every drawing format in use today has a title block with a standard set of block tolerances. The purpose of these block tolerances is to give the engineer a simple method of indicating which dimensions are of higher importance and need to be held to a higher tolerance and which are of lesser importance and don’t need to be held as tightly. As Louis stated in his email to us: “Many of our designers do not take advantage of 2 place and 3 place dimensions. Many still go to 3 decimal places where they could easily cut the tolerances back to 2 places or even 1 place. This makes our machinist have to hold a 3 place decimal where they might have more degrees of freedom. This creates a part that can be more expensive than need be. In a time where money is tight, being a little more careful starts adding up to a nice savings.”

Lou hit the nail right on the head. Many drawings that we see have every single dimension at 3 places, forcing the shop to hold every dimension to whatever the 3 decimal place default tolerance is. In these cases, the designer has failed to use tolerance block to indicate that any dimension is more important to them than others. And as we all know, it is highly unlikely that all features need to be +-.005″ for the part or assembly to work well. The shop making these will spend more time trying to get all dimensions to meet a .005″ tolerance when it is not necessary. The estimator knows this will be the case and will likely quote a higher price for these than they would if they see a mixture of one, two and three significant digits on the drawing. I know first hand in our company this will also lead to discussions of design intent and trying to guess what is more important to the designer so we can make decisions about which are in-line with what the customer wants. But it is very wasteful to engage multiple people in a discussion when you don’t have real information from the customer.

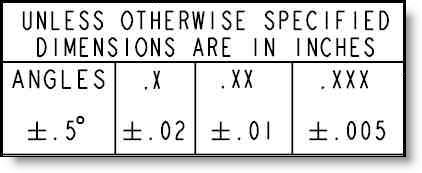

Figure A: Typical Drawing Tolerance Block.

Leaving most of your dimensions at 3 decimal places is faster and easier for you. But we can run the numbers on a typical part we see. Let’s say you have a drawing with 60 dimensions. If it would take 1 minute to decide on each dimension whether or not to change the number of digits then you would spend 1 hour. If your “cost” is $100/hr then you have spent $100 of your company’s money to optimize the number of digits. Let’s also say your part costs $100 and you need 200 of them per year. If that optimization can save 5% of the cost (which is very realistic) then you have saved $1,000 the first year by spending that one hour. We’ve seen tens of thousands of dollars per year saved with just a few hours of time spent. The ROI (return on investment) indicates that this is time very well spent. Some parts might not benefit as much, but most of them we have seen are well worth spending the time to do this.

Most companies employ barely enough engineers to get the job done and the pressure is on to get new projects out the door. So, you might feel like there isn’t enough time to spend on optimizing the tolerances on your drawing. But consider this: it is likely you may get a phone call from your machine shop asking about loosening up some tolerances. The time you had to spend on the back end of the project may be more than the initial investment to develop a well thought out tolerance plan.

As we have discussed in earlier newsletters, sticking to the title block is not the only way to communicate the specific tolerances you need. Using Figure A as an example, if you had a dimension that you couldn’t tolerate +-.010″ (using 2 significant digits won’t work) but you also didn’t need it to be as good as +-.005″ (using 3 digits is overkill) then go ahead and use something in between. Maybe a .007″ tolerance would work in your application and would allow the shop to use a different type of tool or a different method for cutting the parts that will save a lot of time. You never know where the savings can come from so give as much tolerance as you can and you might be pleasantly surprised at how smoothly it goes and how much money you save.

Every month we feature a really cool part that we have made. September’s Part of the Month is a machined display housing. This large part includes machining from many sides, lots of heat sink fins and threaded holes with stainless steel inserts installed. This 40 pound block of aluminum weighs less than 2 pounds when finished.