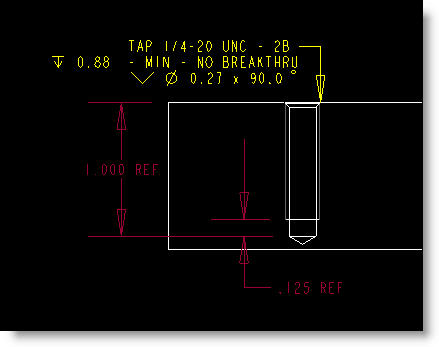

July 2009 – Countersinks and Chamfers

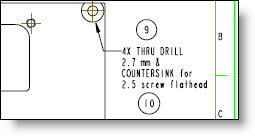

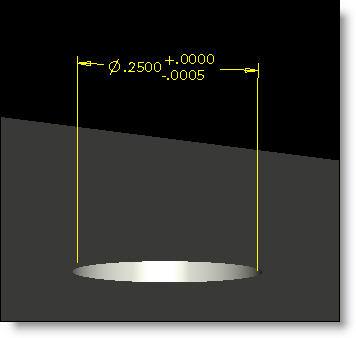

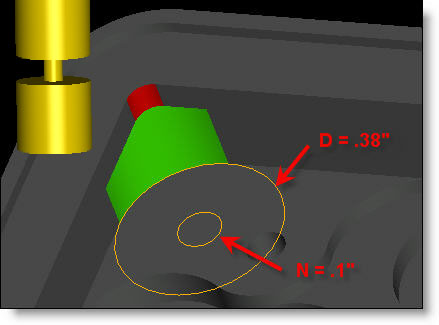

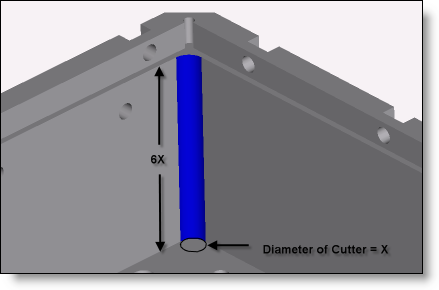

Last month’s newsletter discussed bilateral vs unilateral tolerances. This month we are going to cover a fairly simple topic – countersinks, chamfers and the tolerances of these types of features. Any machined part that has holes in it probably also has countersinks. Countersinks are used as a lead-in for threads, for flathead screws, and just…