May 2010 – Making Simple Drawings

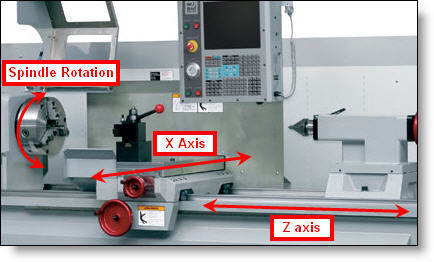

Last month’s newsletter was an overview of turning centers. This month we are going to look at ways to simplify your drawings with the express purpose of reducing the cost of manufacturing and inspection. I am going to make an assumption for the sake of this newsletter that the machine shop making your parts is…